- This topic is empty.

-

AuthorPosts

-

2025-09-02 at 5:51 pm #4457

In the plastics processing and recycling industry, the efficient grinding and pulverizing of materials play a crucial role in achieving high-quality end products. Among the many machines used for this purpose, disc type PP grinders have become widely adopted due to their high efficiency, precision, and ability to handle various thermoplastic materials such as polypropylene (PP), polyethylene (PE), and polyvinyl chloride (PVC).

However, to fully maximize the performance of disc type PP grinders, it is essential to understand their working principles, operating procedures, maintenance requirements, and best practices for safe and efficient usage. This step-by-step guide provides a comprehensive look into how to operate these machines effectively while also highlighting the expertise of Wuxi Songhu Xinrui Machinery Co., Ltd., a leading manufacturer of PE millers and PVC crusher equipment.

What Are Disc Type PP Grinders?

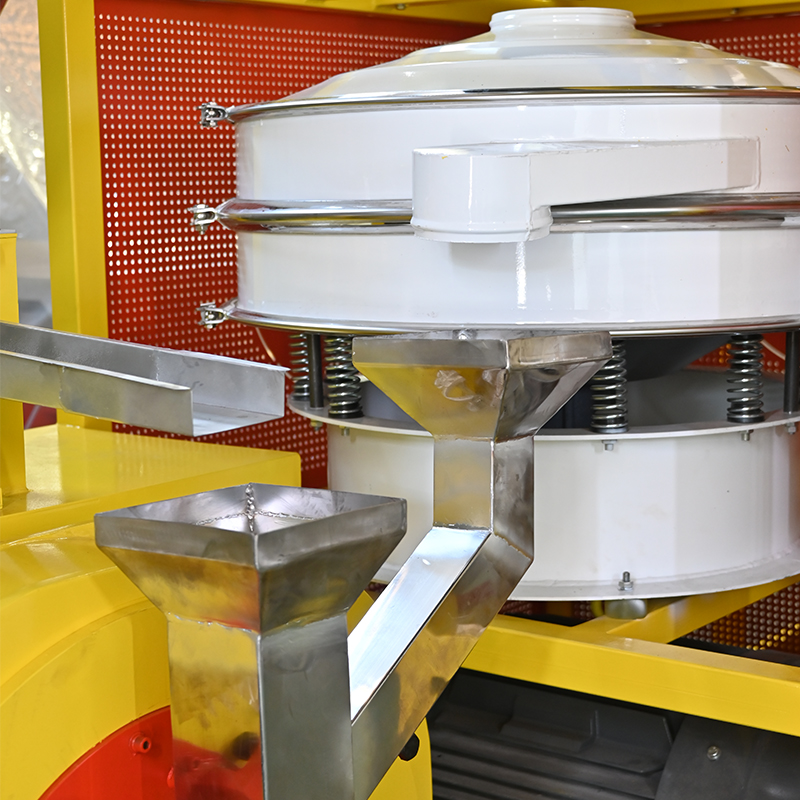

Disc type PP grinders are precision milling machines designed to pulverize plastic materials into fine powders. These machines utilize high-speed rotating discs to crush, grind, and refine materials, making them suitable for:

Plastic recycling plants

Injection molding production lines

Film and sheet processing

Masterbatch and compounding industries

Key Features

High-speed disc grinding system

Adjustable gap for desired fineness

Efficient cooling mechanisms to prevent material degradation

Compact design for easy installation and operation

Wuxi Songhu Xinrui Machinery Co., Ltd. specializes in designing and manufacturing advanced PP grinders with optimized disc configurations, ensuring high output and consistent particle size.

Why Use Disc Type PP Grinders?

Benefits

High Efficiency – Capable of processing large volumes of PP materials quickly.

Consistent Output – Delivers uniform powder sizes ideal for downstream processes.

Versatility – Suitable for a variety of plastic materials, including PE, PVC, and ABS.

Cost-Effectiveness – Reduces material waste and improves recycling rates.

Energy Efficiency – Designed with modern motors and cooling systems to reduce energy consumption.

Applications

Recycling of plastic scraps and defective products

Production of fine powders for film blowing or extrusion

Powder coating raw material preparation

PVC and PE compounding

Step-by-Step Guide to Operating Disc Type PP Grinders

Operating a disc type PP grinder requires proper setup, regular monitoring, and adherence to safety guidelines. Below is a detailed procedure for efficient operation.

Step 1: Pre-Operational Preparation

Inspect the Machine: Check for loose bolts, damaged parts, or abnormal wear on grinding discs.

Ensure Cleanliness: Remove any residual materials or debris inside the chamber.

Verify Cooling Systems: Ensure that the air or water cooling systems are functioning properly.

Check Power Supply: Confirm that the machine is connected to a stable and adequate power source.

Step 2: Material Preparation

Sort Materials: Separate PP from other plastics to avoid contamination.

Pre-Clean the Materials: Remove dust, metal particles, or impurities.

Pre-Dry if Necessary: Ensure moisture content is minimized to prevent clumping.

Step 3: Machine Setup

Adjust the disc gap according to the desired fineness.

Set the feeding rate to match material flow requirements.

Calibrate the temperature and airflow settings to avoid overheating.

Step 4: Start-Up Procedure

Turn on the cooling system.

Start the grinder motor without feeding material initially.

Gradually introduce PP material into the hopper.

Monitor the grinding process for stable operation.

Step 5: Monitoring During Operation

Watch for abnormal vibrations or sounds.

Ensure temperature remains within safe limits.

Check powder output quality regularly.

Step 6: Shutdown Procedure

Stop feeding materials.

Allow the grinder to run empty for a few minutes to clear remaining materials.

Turn off the motor and cooling systems.

Perform a quick inspection for wear or residue buildup.

Maintenance Best Practices

Proper maintenance extends the life of your PP grinder and ensures consistent performance.

Daily Maintenance

Clean grinding discs and chambers after each use.

Lubricate moving parts if required.

Weekly Checks

Inspect grinding discs for wear or damage.

Tighten bolts and connections.

Monthly Maintenance

Replace worn-out discs.

Check motor bearings and belts.

Inspect cooling systems for leaks or blockages.

Wuxi Songhu Xinrui Machinery Co., Ltd. offers durable PP grinder models designed for low maintenance needs and provides genuine spare parts for long-term reliability.

Safety Guidelines for Operating PP Grinders

Always wear protective gear: gloves, goggles, and ear protection.

Do not overload the machine beyond its rated capacity.

Avoid using the grinder for incompatible materials.

Keep unauthorized personnel away from operating zones.

Ensure proper ventilation to dissipate heat.

Common Issues and Troubleshooting

Overheating

Cause: Excessive feed rate, poor ventilation.

Solution: Reduce feeding speed; check cooling systems.

Uneven Powder Size

Cause: Incorrect disc gap settings or worn-out discs.

Solution: Adjust gap; replace discs if necessary.

High Energy Consumption

Cause: Blunt discs or clogged airflow.

Solution: Clean and maintain machine regularly.

Noise and Vibrations

Cause: Loose components or unbalanced discs.

Solution: Tighten parts; balance or replace discs.

Advantages of Choosing Wuxi Songhu Xinrui Machinery Co., Ltd.

When investing in disc type PP grinders, the choice of manufacturer makes a significant difference in overall performance and cost-efficiency.

Why Wuxi Songhu Xinrui?

Expertise: Specialized in PE millers, PVC crushers, and PP grinders.

High-Quality Engineering: Robust design with advanced disc technology.

Customization: Machines tailored for different production needs.

Energy Efficiency: Low power consumption with high output.

After-Sales Support: Comprehensive technical assistance and spare parts supply.

By selecting equipment from Wuxi Songhu Xinrui Machinery Co., Ltd., customers benefit from machines that deliver long-term durability, stable performance, and superior grinding results.

Enhancing Efficiency with Best Practices

To get the most out of your disc type PP grinder:

Train Operators: Ensure staff are well-trained in machine operation.

Implement Regular Maintenance Schedules: Prevent unexpected breakdowns.

Optimize Material Preparation: Cleaner, drier materials grind more efficiently.

Leverage Monitoring Technology: Use sensors and performance tracking systems.

Work with Trusted Suppliers: Choose machinery with proven track records.

Future Trends in Plastic Grinding Technology

Automation & Smart Controls: Integration with Industry 4.0 systems for predictive maintenance.

Eco-Friendly Design: Lower energy consumption and noise pollution.

High-Speed Precision Grinding: Improved disc materials for higher throughput.

Hybrid Grinding Systems: Machines capable of handling multiple material types efficiently.

Wuxi Songhu Xinrui is actively innovating in these areas, ensuring that its customers stay ahead in a competitive and environmentally conscious market.

Conclusion

Operating a disc type PP grinder efficiently is not only about turning the machine on and feeding material—it requires proper preparation, precise adjustments, continuous monitoring, and regular maintenance. When executed correctly, this process can significantly boost productivity, reduce costs, and improve the quality of your final products.

Choosing a reliable manufacturer is equally important. Wuxi Songhu Xinrui Machinery Co., Ltd., with its expertise in producing PE millers, PVC crushers, and disc type PP grinders, stands as a trusted partner for industries seeking high-performance, durable, and energy-efficient grinding solutions. Whether you are starting a new production line or upgrading your existing facility, their advanced machinery and professional support can help you achieve consistent, high-quality results.

How to Choose the Right Disc Type PP Grinder for Your Needs

http://www.songhuxr.com

Wuxi Songhu Xinrui Machinery Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.