- This topic is empty.

-

AuthorPosts

-

2025-09-01 at 3:27 pm #4441

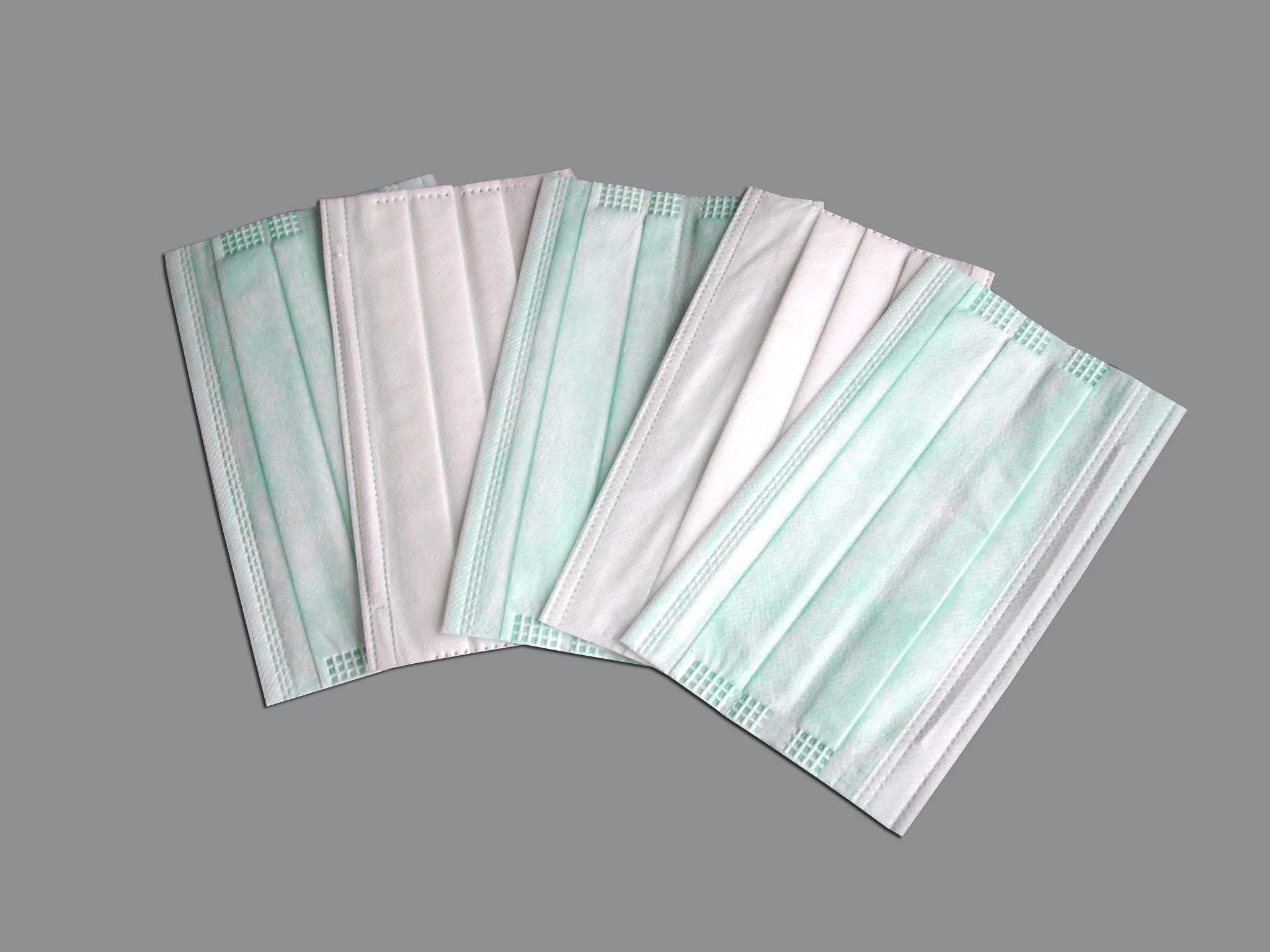

The global demand for medical protective equipment has risen sharply in recent years, and with it, the importance of efficient mask production technology. Among the core equipment in mask manufacturing lines, the Mask Blank Body Making Machine stands out as a vital solution. It is the foundation for producing high-quality mask blanks before the earloop welding and packaging processes. This article explores the technical features, practical benefits, and why leading enterprises like Broadfair Automation Equipment Co., Ltd. have become trusted partners in this industry.

Technical Features of Mask Blank Body Making Machine

High-Speed Automation

Modern machines integrate servo-driven systems and precision sensors to achieve stable, high-speed operation. This ensures continuous production with minimal downtime.

Multi-Layer Processing Capability

The machine can handle multiple layers of nonwoven fabrics, melt-blown fabric, and filter material simultaneously. This is essential for producing masks with effective filtration and breathability.

Precision Cutting and Ultrasonic Welding

Advanced ultrasonic welding technology provides seamless bonding of mask layers, guaranteeing durability without compromising comfort. Precision cutting ensures uniform shapes and dimensions across every mask blank.

User-Friendly Control Systems

Equipped with intelligent PLC controls and touch-screen interfaces, operators can easily adjust parameters, monitor performance, and detect issues in real time.

Stable and Durable Structure

With high-grade steel frames and modular components, these machines are designed for long-term performance, easy maintenance, and reduced vibration during production.

Practical Benefits for Manufacturers

Enhanced Productivity

Automated mask blank making machines can produce thousands of blanks per hour, enabling manufacturers to meet market demand efficiently.

Consistent Quality

Uniform shaping and strong ultrasonic welding reduce defects, ensuring every mask meets safety and medical standards.

Cost-Effectiveness

By minimizing labor requirements and material wastage, manufacturers can reduce operational costs while increasing output.

Flexibility and Customization

Machines can be adapted to different mask designs, including flat masks, KN95 blanks, and other variations, allowing manufacturers to diversify product offerings.

Compliance with International Standards

With precision engineering, the equipment helps ensure masks meet regulatory requirements, giving manufacturers a competitive edge in both domestic and international markets.

Broadfair Automation Equipment Co., Ltd.: Driving Innovation

As a high-tech enterprise integrating R&D, production, and sales, Broadfair Automation Equipment Co., Ltd. has established itself as a leader in mask-making solutions. The company combines cutting-edge automation technology with practical production experience to deliver equipment that is reliable, efficient, and adaptable to evolving industry needs.

Broadfair’s commitment to innovation is reflected in its continuous improvements to equipment design, ensuring clients benefit from:

Stable and efficient mask blank body production lines.

Customized solutions tailored to client requirements.

Professional after-sales service and technical support.

Through its dedication, Broadfair has earned trust from clients worldwide, helping them achieve both quality assurance and large-scale production capacity.

Conclusion

The Mask Blank Body Making Machine is not just an essential piece of equipment—it is the backbone of mask manufacturing. With advanced features such as high-speed automation, ultrasonic welding, and user-friendly control systems, it delivers significant benefits in productivity, cost efficiency, and quality assurance.

Companies like Broadfair Automation Equipment Co., Ltd. continue to play a pivotal role in the industry, offering reliable solutions that empower manufacturers to meet global demands. For businesses aiming to stay competitive in the mask production sector, investing in advanced automation equipment is a smart and strategic choice.

Key Considerations When Choosing a Mask Blank Body Making Machine

http://www.broadfairmachine.com

Broadfair Automation Equipment Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.