- This topic is empty.

-

AuthorPosts

-

2025-09-05 at 6:18 pm #4549

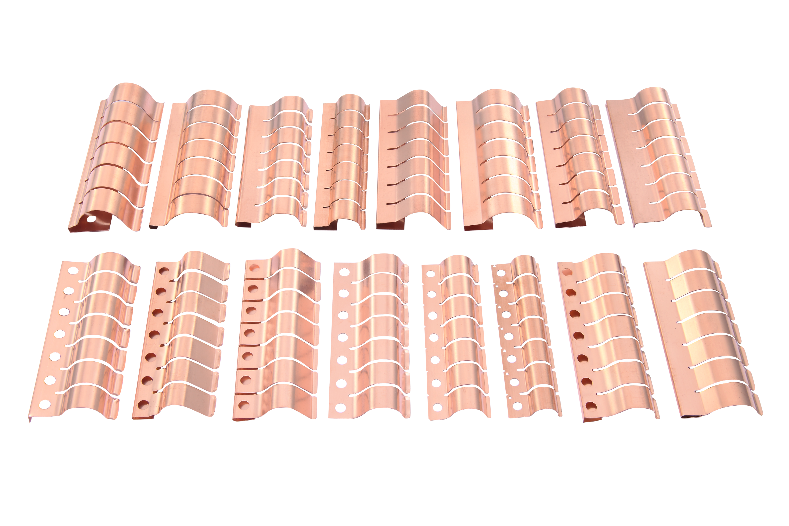

With the increasing requirements of electronic products for electromagnetic compatibility (EMC), shielded rooms (EMI Shielding Room) play a vital role in high-precision measurement, communication equipment testing, medical electronics and other fields. In the construction of shielded rooms, an inconspicuous but extremely critical component-Beryllium copper reed (Beryllium Copper Fingerstock) is becoming a core solution to improve shielding performance and service life.

What is a beryllium copper spring?

Beryllium copper springis an elastic metal contact made of beryllium copper alloy (usually C17200). It has the characteristics of high strength, high conductivity, high elasticity and good corrosion resistance. It is often used in movable interfaces, door gaps, and panel connections of electromagnetic shielding. It not only provides a low-impedance electrical connection between the shielded room door and the door frame, but also takes into account durability and mechanical stability.

Core advantages of beryllium copper spring

1. Excellent elasticity and deformation recovery

Even under long-term compression, beryllium copper reed can still maintain stable resilience, ensure close fit of contact surface, and effectively prevent electromagnetic leakage.

2. High shielding effectiveness (>100 dB)

Its excellent conductivity enables it to maintain excellent shielding effect in the frequency band of 10kHz to 10GHz, which is especially suitable for high-frequency equipment testing environment.

3. Excellent corrosion resistance and long life

Beryllium copper has good oxidation resistance and corrosion resistance, and can work stably for a long time even in high humidity, high salt fog or industrial pollution environment.

4. Flexible installation and various specifications

It provides a variety of installation methods such as clip-on, guide rail, and adhesive, supports standard size and non-standard customization, and is easy to integrate into shielding doors, cabins or corners of different structures.

5. Rich surface treatment

It can provide a variety of electroplating processes such as gold plating, silver plating, nickel plating, and tin plating to meet different contact resistance and environmental requirements.

Application areas

• Shielding test room door seal

• Communication cabinet, switching system connector

• Medical equipment shielding structure

• Avionics equipment EMC design

• Precision instruments and laboratory protection system

Why is beryllium copper springbetter than other materials?

Compared with stainless steel reeds and phosphor copper reeds, beryllium copper has a higher elastic fatigue limit and stronger conductivity. It can achieve higher shielding efficiency with a smaller contact surface. It is one of the preferred reed materials in current high-end EMI applications.

If you need to obtain samples, technical parameters or cooperation consultation, please visit the official website [www.emis-tech.com] or contact email[sales@emis-tech.com]

http://www.emi-gasketech.com

ShenZhen EMIS Electronics Materials Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.