- This topic is empty.

-

AuthorPosts

-

2025-12-19 at 9:43 am #5667

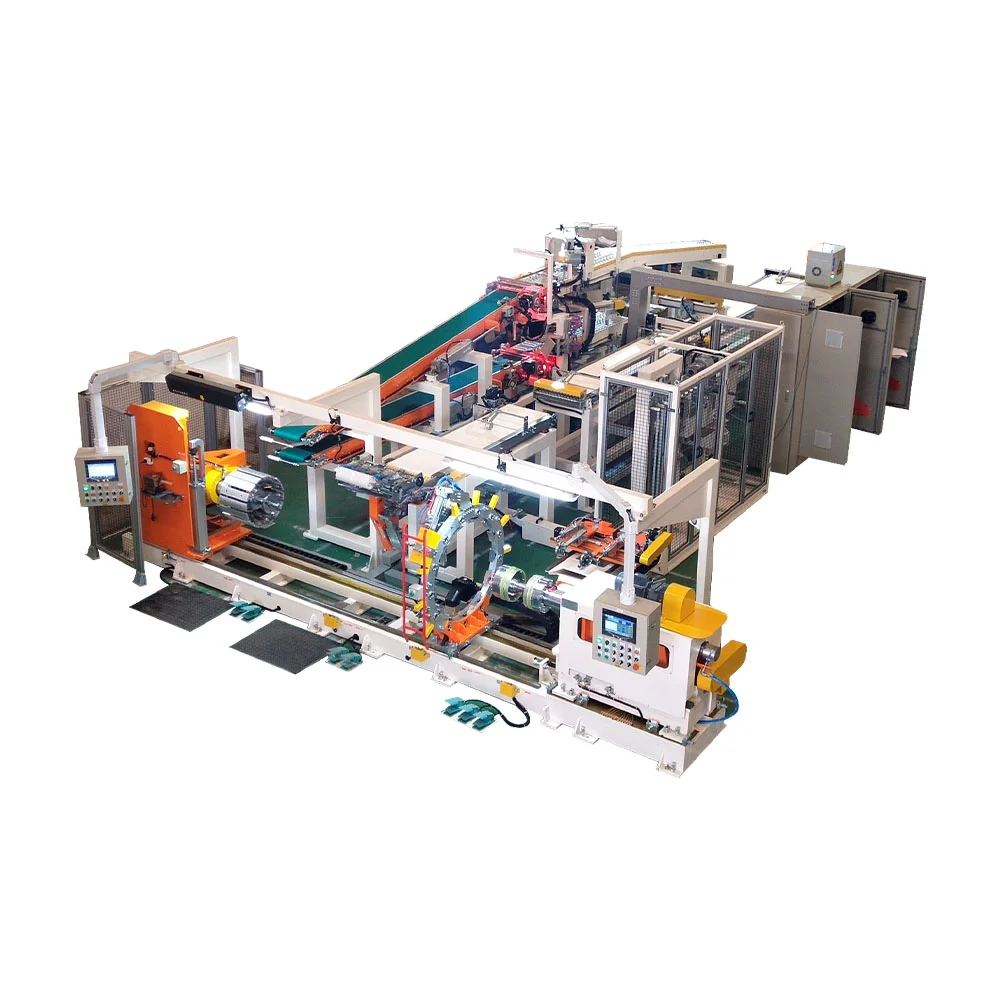

Role of Second-Stage Tire Building Machine in Tire Manufacturing

Within a typical tire production line, the second-stage process is where structural integrity is finalized. After the first-stage carcass is prepared, the second-stage tire building machine applies belts, tread, and crown strips, ensuring accurate positioning and uniform tension. Any deviation at this stage can directly affect tire balance, durability, and high-speed performance.

Unlike earlier generations of equipment, modern second-stage systems are designed to handle a wide range of tire categories—from passenger car HP and UHP tires to SUV and off-road MT/AT models. This flexibility allows manufacturers to respond quickly to market demand while maintaining consistent quality across product lines. In this blog post, SONIWELL, as high performance tire manufacturing equipment exporter, will share the features of high precision second-stage tire building machine for tire plants.

High Precision Design for HP, UHP, SUV, MT, and AT Tires

High-performance tires demand extremely tight tolerances. A high precision second-stage tire building machine addresses this requirement through rigid mechanical design and fully servo-driven motion systems. Servo motors are used across the main engine, rear pressure mechanism, and transmission units, enabling smooth acceleration, precise positioning, and stable torque output.

For UHP and SUV tires, where belt alignment and crown geometry are critical, servo control ensures that each component is applied with repeatable accuracy. For MT and AT tires, which often involve thicker treads and complex crown structures, the machine maintains consistent forming pressure, preventing deformation during the building process.

Intelligent Control Systems Supporting Process Stability

Control architecture is a key differentiator in modern second-stage tire building equipment. Optional control platforms such as MITSUBISHI, SIEMENS, or Allen-Bradley (AB) allow manufacturers to integrate the machine seamlessly into existing automation environments.

These control systems support real-time monitoring, recipe management, and fault diagnostics. Operators can quickly switch between tire specifications, reducing downtime during product changeovers. At the same time, process data collected by the control system provides valuable input for quality analysis and continuous improvement initiatives.

Automatic Deviation Correction for Belt Feeding Accuracy

Belt placement accuracy is essential to tire uniformity. Modern second-stage tire building machines are equipped with automatic deviation correction systems for the belt feeding rack. During operation, sensors continuously monitor belt position, and corrective adjustments are applied instantly to prevent lateral drift.

This closed-loop correction mechanism significantly reduces scrap rates caused by misaligned belts. It also minimizes the need for manual intervention, allowing operators to focus on process supervision rather than constant adjustment.

Pre-Cutting and Automatic Belt Drum Technologies

Efficiency in second-stage operations depends heavily on material preparation and handling. Pre-cutting functions integrated into the machine ensure that belt lengths are prepared accurately before application. This reduces cycle time and improves consistency from tire to tire.

Automatic belt drum systems further enhance productivity. With optional joint detection, the belt drum can identify joint positions and coordinate them precisely during application. This capability is particularly important for high-speed and high-load tires, where joint placement influences structural balance and fatigue resistance.

Servo-Driven Transmission and Rear Pressure Mechanisms

The adoption of full-range servo systems represents a major advancement in second-stage tire building technology. Servo-driven transmission mechanisms provide precise control over rotational speed and torque, enabling smooth and stable tire forming.

Similarly, servo-controlled rear pressure mechanisms ensure uniform pressure distribution during molding. This contributes directly to improved tire roundness and reduced variation in final dimensions. Compared with traditional hydraulic systems, servo solutions also offer faster response times and improved energy efficiency.

Crown Strip Tension Control with Displacement Sensors

Crown strip application requires careful tension management to avoid stretching or wrinkling. In high precision second-stage tire building machines, crown strip tension is controlled using displacement sensors combined with proportional valves. This system allows precise adjustment within a range of 5–50 N.

By maintaining stable tension throughout the laying process, the machine ensures consistent crown geometry and enhances bonding quality between layers. This level of control is especially valuable for UHP tires, where even minor inconsistencies can affect high-speed stability.

Flexible Belt Top and Bottom Configuration Options

Different tire designs require different belt configurations. Modern second-stage equipment supports both belt top and belt bottom selection, giving manufacturers the flexibility to adapt to various structural designs.

This configurability reduces the need for multiple dedicated machines, helping plants optimize floor space and capital investment. With recipe-based control, switching between configurations can be achieved quickly and reliably.

Multiple Crown Strip Laying Methods for Diverse Tire Designs

Tire manufacturers often serve multiple markets with distinct performance requirements. To meet these needs, advanced second-stage tire building machines offer various crown strip laying methods. These methods can be selected according to tire type, tread design, and performance objectives.

Whether the focus is high-speed stability, off-road durability, or noise reduction, flexible crown strip application supports tailored tire structures without compromising production efficiency.

CCD Camera Systems for Automatic Belt Deviation Correction

Visual inspection technology has become an integral part of modern tire building. CCD camera systems installed on second-stage machines continuously monitor belt alignment during application. When deviation is detected, the system automatically corrects the belt position in real time.

This non-contact inspection approach enhances accuracy while reducing wear on mechanical components. It also provides visual records that can be used for quality audits and process optimization.

Ultrasonic Cutting and Heated Tread Joints

Cutting quality directly influences tread bonding strength. Ultrasonic cutting technology enables clean, precise cuts with minimal material deformation. Compared with conventional cutting methods, ultrasonic systems reduce burrs and improve joint consistency.

In addition, heating the head and tail of the tread incision enhances bonding during assembly. This combination of ultrasonic cutting and controlled heating contributes to stronger joints and improved tire durability, particularly under high-speed or heavy-load conditions.

Production Efficiency and Quality Balance in Second-Stage Equipment

A well-designed second-stage tire building machine strikes a balance between speed and precision. Automation features such as deviation correction, servo-driven motion, and intelligent control reduce cycle times while maintaining strict quality standards.

As a result, manufacturers can achieve higher throughput without sacrificing consistency. Reduced rework, lower scrap rates, and stable process control translate directly into cost savings and improved competitiveness.

Future Trends in Second-Stage Tire Building Technology

Looking ahead, second-stage tire building machines are expected to become even more intelligent. Integration with manufacturing execution systems (MES), predictive maintenance algorithms, and advanced data analytics will further enhance process transparency.

At the same time, demand for flexible equipment capable of handling diverse tire categories will continue to grow. Machines that combine high precision, automation, and adaptability will be best positioned to support evolving market needs.

Conclusion

The second-stage tire building machine is no longer just a forming unit; it is a critical platform for precision manufacturing. Through servo-driven systems, intelligent control options, automatic deviation correction, and advanced cutting technologies, modern second-stage equipment supports the production of high-performance tires with consistent quality and efficiency.

For manufacturers targeting HP, UHP, SUV, MT, and AT segments, investing in high precision second-stage technology provides a solid foundation for meeting stringent performance standards while remaining agile in a competitive global market.

http://www.soniwellgroup.com

SONIWELL -

AuthorPosts

- You must be logged in to reply to this topic.