- This topic is empty.

-

AuthorPosts

-

2026-02-06 at 6:21 pm #6353

In today’s fast‑paced construction industry, the demand for efficient, durable, and cost‑effective structural solutions has never been higher. One innovation that has gained prominence in modern building design is the waffle slab — a reinforced concrete floor system known for its strength, reduced material usage, and architectural flexibility. At the heart of successful waffle slab construction is precision formwork, and companies like SUZHOU BOGUAN YUEOU INTELLIGENT EQUIPMENT CO., LTD. provide advanced solutions that elevate project performance. For an overview of the company’s expertise, see: https://www.szformwork.com/About-Us.html.

In this article, we explore the design principles of waffle slab formwork, its applications, and how intelligent formwork solutions are shaping the future of structural projects.

What Is a Waffle Slab?

A waffle slab — also called a two‑way joist slab — is a reinforced concrete slab characterized by a grid of ribs on both directions, creating a “waffle‑like” appearance from below. This unique geometry combines structural efficiency with aesthetic appeal.

Compared to flat slabs, waffle slabs offer:

-

Higher load‑bearing capacity with reduced material volume

-

Larger column‑to‑column spans

-

Improved stiffness and vibration control

These qualities make waffle slabs ideal for structures such as auditoriums, parking garages, office buildings, and public halls where open spaces and high structural integrity are required.

Design Principles of Waffle Slab Formwork

Effective waffle slab construction begins with well‑designed formwork. Formwork serves as the temporary mold that supports wet concrete until it gains strength. For waffle slabs, formwork must:

1. Maintain Rib Accuracy

The grid pattern of ribs must be precisely formed to ensure uniform stiffness and load distribution. Any irregularity can compromise structural performance.

2. Withstand Construction Loads

Formwork must support the weight of concrete, reinforcement, and workers — all while maintaining dimensional stability.

3. Allow Easy Assembly and Disassembly

Efficient formwork systems reduce labor time and project costs.

4. Be Reusable and Durable

High‑quality materials extend the life of the formwork and reduce long‑term costs.

Innovative manufacturers like SUZHOU BOGUAN YUEOU INTELLIGENT EQUIPMENT CO., LTD. specialize in designing modular, high‑precision formwork that meets these stringent requirements. Their systems are engineered for repeatability, strength, and ease of use — reflecting decades of industry experience.

Key Components of Waffle Slab Formwork

Waffle slab formwork typically consists of:

Formwork Panels

These are flat or ribbed panels that define the flat surface and the grid pattern. Materials can include plywood, steel, or engineered composites depending on strength and reuse needs.

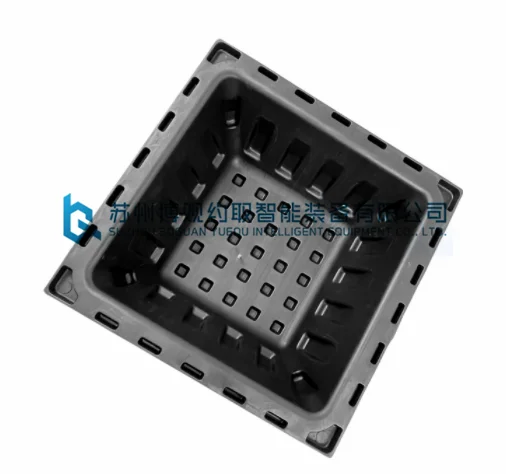

Modular Void Formers

Lightweight void formers create the recesses between ribs, reducing concrete volume without sacrificing strength. These can be made of plastic, foam, or engineered materials.

Support Props and Beams

Adjustable props and beams provide vertical and horizontal support during concrete placement.

Fasteners and Connectors

Reliable fasteners ensure alignment and stability of the formwork grid.

Advanced formwork systems prioritize quick assembly, integrated alignment features, and secure connections to streamline construction while maintaining quality.

Applications in Modern Structural Projects

The versatility and performance of waffle slabs — especially when paired with efficient formwork — make them suitable for a wide range of projects:

Commercial Buildings

Waffle slabs support large floor areas with minimal columns, allowing flexible interior layouts.

Public Spaces

Auditoriums, museums, and exhibition halls benefit from the open spans and architectural appeal of waffle slabs.

Parking Structures

The high load capacity and durability of waffle slabs make them ideal for multi‑level parking facilities.

Educational and Institutional Buildings

Large classrooms, libraries, and assembly halls often require structures that balance strength with aesthetic design — a perfect niche for waffle slabs.

Benefits of Intelligent Formwork Systems

Modern formwork technologies — like those developed by SUZHOU BOGUAN YUEOU INTELLIGENT EQUIPMENT CO., LTD. — bring additional advantages to waffle slab construction:

Reduced Construction Time

Pre‑engineered components and modular designs cut down assembly and stripping times, helping projects stay on schedule.

Improved Quality Control

Precision formwork ensures consistent rib sizes and flatness, reducing rework and improving structural integrity.

Cost Efficiency

Reusability and faster installation lead to significant savings in labor and materials.

Enhanced Safety

Ergonomic design, standardized components, and reliable support systems reduce on‑site risks.

By integrating intelligent design, precision manufacturing, and user‑friendly features, advanced formwork systems support both traditional and cutting‑edge construction approaches.

Common Questions About Waffle Slab Formwork

What makes waffle slabs different from traditional slabs?

Waffle slabs include a grid of ribs that enhance load capacity and allow larger spans than conventional flat slabs.

Why is formwork precision important for waffle slabs?

Accurate formwork ensures uniform rib geometry, which is essential for structural performance and load distribution.

Can waffle slab formwork be reused?

Yes — well‑designed systems use durable materials that can be reused across multiple pours, improving cost efficiency.

Are waffle slabs suitable for all building types?

While extremely versatile, waffle slabs are most beneficial in structures requiring wide open spaces and high load performance.

Final Thoughts

Waffle slab formwork plays a pivotal role in shaping modern structural projects. By combining advanced engineering, precise design, and durable materials, contemporary formwork systems make it possible to achieve complex architectural and structural goals with efficiency and reliability.

AuthorPostsViewing 1 post (of 1 total)- You must be logged in to reply to this topic.

-