- This topic is empty.

-

AuthorPosts

-

2025-11-26 at 6:22 pm #5349

https://www.ascendtechs.com/ascend-temperature-control-module.html

In the lithium battery production process, the precision of the liquid injection process directly affects battery performance and consistency. Many customers have found during production that the liquid injection volume often deviates due to fluctuations in electrolyte density — temperature changes (such as seasonal temperature differences and variations in electrolyte storage environments) cause changes in electrolyte density. Even with dynamic closed-loop variable liquid injection, it is still difficult to avoid fluctuations in the actual liquid injection volume.

To address this challenge, Guangzhou Ascend has added the Ascend Temperature Compensation Module at the front end of the constant flow pump. It precisely monitors the electrolyte temperature and adjusts the liquid injection accordingly, offsetting the impact of density changes on the injection volume.

This module boasts the following core advantages:

1.High-precision sensing, exceeding industry standards

It adopts a Pt1000 platinum resistance temperature sensor. Compared with traditional Pt100 sensors, it has higher sensitivity of resistance change with temperature and significantly improved measurement accuracy, providing a more precise data foundation for the temperature control system.

2.Ultra-fast response for dynamic capture of temperature changes

The sensor's response time reaches t05 ≤ 1 second and t09 ≤ 3 seconds (i.e., the time to achieve 50% and 90% response), which is far beyond the response speed of conventional sensors, enabling instantaneous capture and real-time compensation of temperature fluctuations.

3.Withstands extreme working conditions, delivering impeccable quality

The module can withstand pressure up to 40MPa, far exceeding the pressure resistance standards of similar products. It easily copes with high-pressure challenges in complex production environments, ensuring long-term stable operation.

4.Closed-loop control with dynamic compensation

Through a dynamic monitoring and compensation algorithm, closed-loop control of the injection volume is achieved, confining the fluctuation range to an extremely narrow interval and significantly improving product consistency.

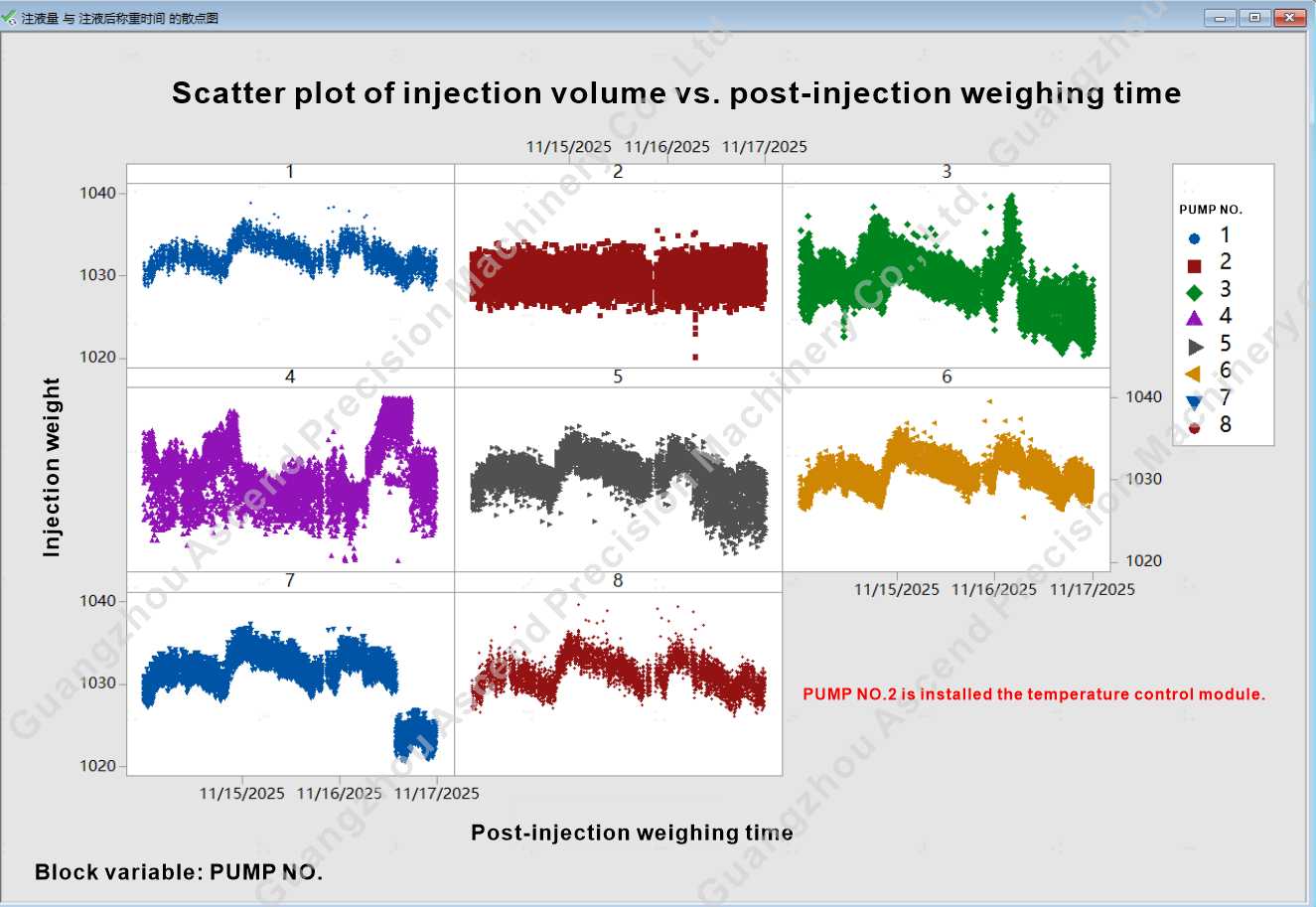

Currently, Ascend Temperature Compensation Modules have been successfully deployed in bulk installations at multiple leading lithium battery enterprises. From the actual production data, it can be seen that Ascend Temperature Compensation Module has significantly improved the stability of the liquid injection process — according to the following customer-measured data, the CPK value of the injection volume has achieved a remarkable increase. The bulk adoption and long-term repeat purchases by leading enterprises serve as the best endorsement for Ascend’s technological strength and product quality.

Ascend empowers customers to overcome process challenges through technological innovation and unwavering commitment to quality, realizing:

● Reduce losses: Reduce raw material waste and rework costs caused by liquid injection deviations.

● Improve yield rate: Stabilize the liquid injection volume to ensure core battery performance such as capacity and cycle life.

● Enhance competitiveness: Win market trust with high-consistency products and support the long-term development of the brand.

Choosing Ascend is not only choosing a product, but also partnering with a companion dedicated to quality and deeply rooted in technology. We refine every detail to rigorous standards, take the choice of leading enterprises as a benchmark, and ensure that every gram of our customers' injection is precisely controllable and every lithium battery is consistently reliable.

https://www.ascendtechs.com/ascend-temperature-control-module.html

Guangzhou Ascend Precision Machinery Co.,Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.