- This topic is empty.

-

AuthorPosts

-

2025-07-08 at 5:48 pm #3884

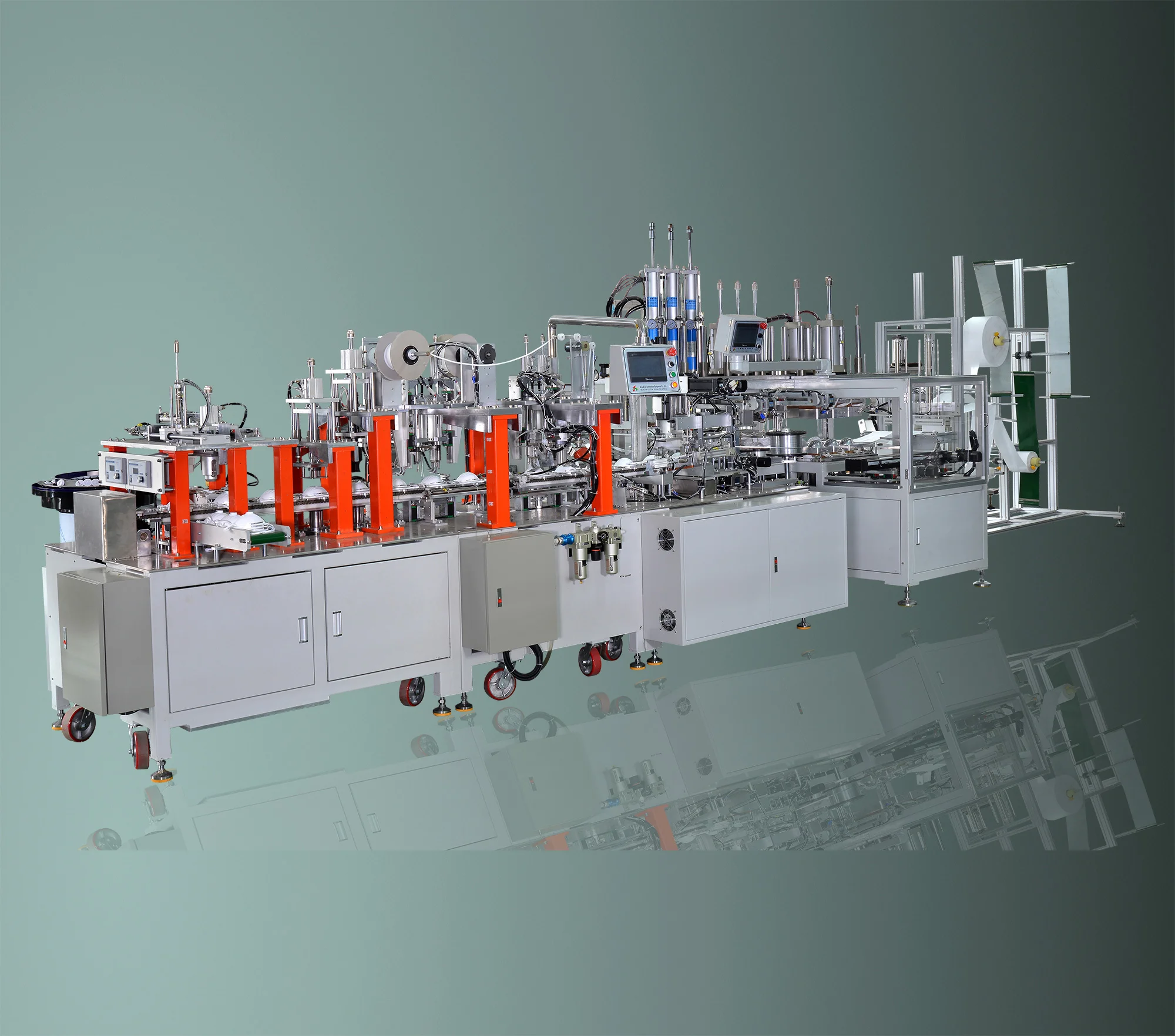

In the rapidly growing personal protective equipment (PPE) industry, the demand for high-quality respiratory masks has never been greater. Among the various types of mask production equipment, the Cup Mask Machine stands out for its precision, efficiency, and reliability. Designed specifically to produce rigid, form-fitting cup-style masks, this machine plays a crucial role in ensuring both comfort and protection for the end user. In this article, we’ll explore the key functions of a cup mask machine and highlight the major benefits it brings to manufacturers aiming for scalable, consistent, and high-performance mask production.

Key Functions of a Cup Mask Machine

A cup mask machine integrates several core functionalities to enable the efficient, high-speed production of cup-shaped masks. The primary functions include:

Automatic Feeding and Cutting: Raw materials such as non-woven fabric and melt-blown cloth are automatically fed into the machine and cut into precise shapes.

Thermoforming: The defining characteristic of a cup mask is its three-dimensional shape. The machine uses high-temperature molding to form the cup shape, ensuring a comfortable and secure fit.

Edge Sealing and Trimming: The machine seals the edges of the mask to prevent fraying and ensures a clean, professional finish.

Nose Clip and Ear Loop Attachment: Automated stations within the machine install the nose clip and either weld or sew the ear loops, depending on the design.

Sterilization and Quality Inspection: Advanced cup mask machines include UV sterilization and vision systems to inspect each mask for defects, ensuring consistent quality.

Stacking and Counting: Finished masks are automatically stacked and counted, simplifying packaging and inventory management.

Benefits of Using a Cup Mask Machine

1. High Efficiency and Productivity

The automation of every step in the production process drastically increases output while reducing manual labor. A single cup mask machine can produce thousands of masks per day with minimal human intervention.

2. Consistency and Quality Assurance

With integrated quality control systems, such as automated defect detection and precise cutting and welding, manufacturers can ensure each mask meets stringent industry standards.

3. Cost Reduction

Although the initial investment may be significant, the long-term savings on labor and material waste result in a lower overall cost per unit.

4. Customization and Flexibility

Modern cup mask machines can be adapted to produce different mask sizes and designs, including models with or without valves, multiple layers, and various material types.

5. Improved Safety and Hygiene

Automation reduces human contact with the product, enhancing hygiene and reducing the risk of contamination—critical for medical-grade masks.

Broadfair Automation Equipment Co., Ltd.: A Trusted Manufacturer

One notable player in the industry is Broadfair Automation Equipment Co., Ltd., a high-tech enterprise that integrates R&D, production, and sales. The company is committed to delivering cutting-edge automation solutions that meet the evolving needs of the personal protective equipment (PPE) industry.

Broadfair's cup mask machines stand out for their advanced design, robust construction, and intelligent control systems. These machines are engineered for durability and precision, backed by a strong R&D team that continually innovates to improve efficiency, reliability, and ease of use.

Clients around the world trust Broadfair not only for their high-quality machinery but also for their exceptional after-sales support and commitment to customer satisfaction. Whether you are a start-up entering the PPE market or an established manufacturer looking to upgrade your production line, Broadfair offers the expertise and equipment to help you succeed.

Conclusion

In a time where quality and efficiency are paramount, investing in a reliable cup mask machine is a smart move for any manufacturer in the PPE sector. With automated features that ensure consistency, hygiene, and high output, and with trusted partners like Broadfair Automation Equipment Co., Ltd., businesses can confidently meet market demands while optimizing production processes.

What Is a Cup Mask Machine? Industrial Use Explained

http://www.broadfairmachine.com

Broadfair Automation Equipment Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.