- This topic is empty.

-

AuthorPosts

-

2025-06-27 at 6:11 pm #3812

In an era where electrical safety, power reliability, and corrosion resistance are critical in infrastructure development, selecting the right earthing components is more important than ever. A well-designed grounding system not only protects sensitive equipment from surges and lightning but also safeguards human life and maintains operational continuity in mission-critical environments. Among the most effective grounding materials available today is the threaded copperbond earth rod, and Sunlightweld has become a globally trusted brand in this segment. Known for quality, compliance, and affordability, Sunlightweld's products set a new industry benchmark.

Why Threaded Copperbond Earth Rods Matter

Proper grounding is fundamental to any electrical system's safety, and the threaded copperbond earth rod plays a vital role in ensuring that safety. It provides a reliable, low-resistance path that effectively channels fault currents, lightning, and transient surges into the earth, thereby protecting equipment and personnel.

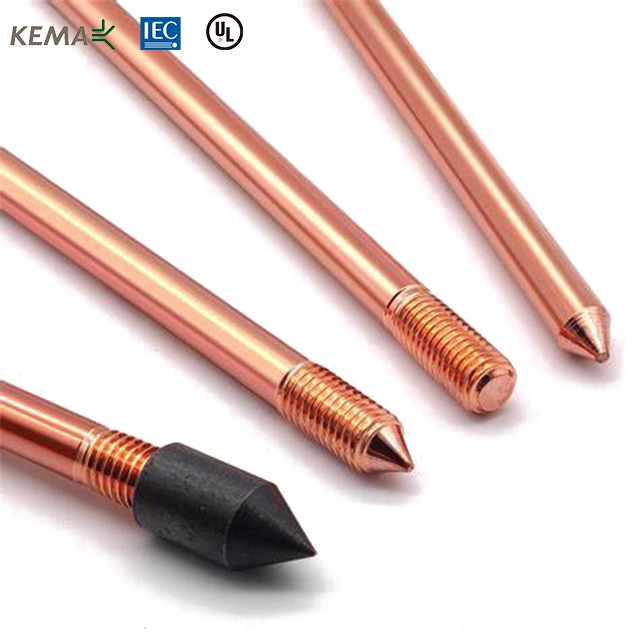

A threaded copperbond earth rod is built with a high-strength steel core bonded to a thick layer of pure copper, combining structural durability with excellent conductivity and corrosion resistance. The threaded ends are designed for secure coupling, allowing multiple rods to be connected easily to achieve greater installation depth when required by soil conditions. This makes the threaded copperbond earth rod especially suitable for vertical grounding applications in demanding environments.

In real-world use, the threaded copperbond earth rod maintains its integrity even under harsh soil and weather conditions. It resists corrosion, ensures long-term electrical continuity, and supports mechanical driving without damaging the copper surface. These features lead to reduced maintenance and extended service life.

Sunlightweld ensures each threaded copperbond earth rod meets international standards such as UL 467 and IEEE 837, combining engineering precision with affordability. This gives contractors and project owners a dependable grounding solution that balances performance with cost-efficiency. The rod's compatibility with standard tools and its ease of installation further enhance its practicality on job sites.

Whether used in substations, telecommunications, industrial settings, or renewable energy systems, the threaded copperbond earth rod remains a cornerstone of modern electrical grounding—reliable, resilient, and ready for the most critical applications.

Sunlightweld Threaded Copperbond Earth Rod Excellence

The performance of any grounding system depends heavily on the materials and engineering behind its components. Sunlightweld threaded copperbond earth rod exemplifies advanced materials science, combining mechanical durability with outstanding electrical properties to deliver exceptional reliability in demanding environments.

Superior Material Composition

At the core of the Sunlightweld threaded copperbond earth rod lies a carefully engineered synergy: a high-purity copper outer layer (99.9%) electroplated onto a robust carbon steel core. This composite design effectively merges the superior conductivity of copper with the tensile strength and driving capacity of carbon steel. The result is a grounding rod that not only performs electrically but also withstands installation forces and long-term mechanical stress in real-world conditions.

Customized Copper Layer Thickness

While the international standard for copper cladding thickness is 0.254mm, Sunlightweld goes further by offering customizable copper thickness options ranging from 0.254mm up to 0.8mm or 0.9mm. This flexibility allows clients to tailor the threaded copperbond earth rod to their site-specific corrosion challenges without excessive cost or unnecessary overengineering. Thicker copper layers offer improved corrosion resistance, ensuring extended operational life even in aggressive soil or chemical environments.

This customization capability gives Sunlightweld a competitive edge, meeting both technical requirements and economic expectations in diverse applications, from high-voltage substations to offshore installations.

Rigorous Certification and Compliance: IEC 62561 and UL

Sunlightweld threaded copperbond earth rod holds dual certification under IEC 62561 and UL standards—an uncommon but highly valuable achievement in the industry. This dual certification signifies full compliance with international safety, structural, and performance benchmarks.

While some manufacturers may meet one set of standards, Sunlightweld delivers both, confirming the product's electrical reliability, corrosion protection, mechanical strength, and long-term durability under a wide range of environmental conditions. This dual compliance also ensures seamless acceptance across global infrastructure projects.

Tensile Strength and Durability

Designed to endure the stresses of real-world installations, Sunlightweld threaded copperbond earth rods provide tensile strength ranging from 350–770 MPa for vertical applications and 290–510 MPa for horizontal applications. These values not only exceed industry minimums but also ensure consistent performance during driving into dense soil, compacted backfill, or rocky terrain.

Excellent Copper Layer Plasticity

In quality testing, Sunlightweld threaded copperbond earth rods undergo a triple 90-degree bending test, confirming that the copper layer remains intact—no cracking, delamination, or peeling—even on both inner and outer curves. This level of ductility enhances safety and usability during handling, transportation, and installation.

Reliable Copper-Steel Bonding

The bond strength between the copper and steel core is another critical quality parameter. Sunlightweld subjects its rods to hammer testing using clamping devices with precise tolerances under 0.1mm. After repeated hammer strikes designed to expose the steel core, the copper layer remains firmly attached with no visible detachment or surface spalling. This confirms the long-term mechanical cohesion essential for field reliability.

Advanced Electrical Performance

In simulated fault current testing—where Sunlightweld threaded copperbond earth rods are exposed to repeated high-current surges—Sunlightweld products demonstrate outstanding resilience.ce growth rate stays under 50% of the initial value, and individual test cycles show less than 15% increase. Most notably, the rods exhibit no external deterioration: no cracks, no bubbling, and no pitting, even under intense electrical stress.

This high-level performance ensures that Sunlightweld threaded copperbond earth rods will maintain their conductivity and structural stability over years of service, even in challenging grounding scenarios involving frequent fault conditions or highly corrosive environments.

Manufacturing and Supply Chain: Why Sunlightweld Stands Out

Sunlightweld's in-house manufacturing ensures full control over key quality factors such as copper purity, plating thickness, thread precision, and surface finish. By eliminating middlemen, the company offers competitive factory-direct pricing. Leveraging China's efficient supply chain, Sunlightweld delivers up to 30% cost savings compared to Western or UL-only certified brands—without compromising quality.

The Sunlightweld threaded copperbond earth rod is more than just a grounding component—it's a culmination of precision engineering, materials science, and value-driven manufacturing. With its customizable specifications, superior mechanical and electrical properties, dual international certification, and unmatched pricing, it has become the go-to solution for electrical grounding engineers around the world. Sunlightweld is not merely a manufacturer—it's a reliable partner in the mission to create safer, more resilient electrical infrastructures. Whether you're a contractor, distributor, or infrastructure developer, choosing Sunlightweld means choosing performance, profitability, and peace of mind.

https://www.sltup.com/Copper-Bonded-Steel-Earth-Rod-Threaded-UL-and-IEC-Listed-Factory-Price.html

http://www.sltup.com

Sunlightweld -

AuthorPosts

- You must be logged in to reply to this topic.